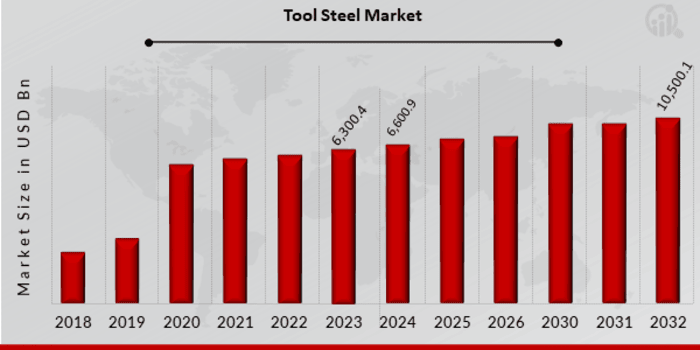

Tool Steel Market Set for 6.0% CAGR Expansion, Surpassing USD 10,500.1 Billion by 2032 | Sandvik, Baosteel, Hitachi

Tool Steel Market

The Tool Steel Market is driven by demand in manufacturing, automotive, and construction, focusing on durability and performance.

COLORADO, CO, UNITED STATES, March 16, 2025 /EINPresswire.com/ -- Market Research Future published a report titled, the Tool Steel Market Size, Share, Competitive Landscape and Trend Analysis Report, by Format Type, Application, Process, and Region: Global Opportunity Analysis and Industry Forecast till 2032. the Tool Steel Market Size was valued at USD 6,300.4 Billion in 2023. The Tool Steel market is projected to grow from USD 6,600.9 Billion in 2024 to USD 10,500.1 Billion by 2032, exhibiting a compound annual growth rate of 6.0% during the forecast period 2024 - 2032.

Tool Steel Market Overview

The tool steel market is a crucial segment of the steel industry, offering specialized steel alloys designed for cutting, shaping, and forming materials. Tool steels are widely used in manufacturing tools, dies, and molds due to their high hardness, wear resistance, and ability to withstand extreme temperatures.

Industries such as automotive, aerospace, construction, and general manufacturing rely on tool steel for precision machining and production. The market is experiencing steady growth, driven by increasing industrialization, technological advancements, and rising demand for high-performance materials across various industries.

Get Free Sample PDF Brochure: https://www.marketresearchfuture.com/sample_request/2754

Key Companies in the Tool Steel market include

Voestalpine AG (Austria)

Sandvik (Sweden)

Baosteel Group (China)

Samuel Son & Co (Canada)

Hitachi Metal (Japan)

Eramet SA (France)

Schmiedewerke Gröditz (Germany)

Universal Stainless (US)

QiLu Special Steel Co. Ltd. (China)

Hudson Tool Steel Corporation (US)

GERDAU S.A. (Brazil)

Pennsylvania Steel Company (US)

Nachi-Fujikoshi Corp (Japan)

Market Trends Highlights

The tool steel market is evolving with several key trends shaping its growth trajectory:

Increased Adoption of High-Speed Steels (HSS): High-speed steels are gaining traction due to their superior wear resistance and heat resistance, making them ideal for high-performance cutting tools.

Growing Demand for Advanced Coatings: The application of coatings like titanium nitride (TiN) and chromium nitride (CrN) on tool steels is enhancing their durability and lifespan, thus boosting market growth.

Rising Use of Powder Metallurgy in Tool Steel Production: Powder metallurgy techniques are increasingly being adopted to manufacture tool steels with enhanced toughness and uniform microstructure, improving their mechanical properties.

Sustainability and Recyclability: With growing environmental concerns, manufacturers are focusing on sustainable and recyclable tool steel solutions to reduce carbon footprints.

Integration of Additive Manufacturing (3D Printing): The use of 3D printing in tool steel production is expanding, allowing for customized tool designs and improved efficiency.

Shift Toward Electric Vehicles (EVs): The growing EV industry is fueling demand for precision machining tools made from tool steel, particularly in battery production and lightweight vehicle components.

Market Dynamics

The tool steel market is influenced by a combination of various dynamic factors, including demand fluctuations, technological innovations, and regulatory policies. The demand for high-performance tool steels is growing in industries requiring precision and durability.

However, the market is also impacted by fluctuating raw material prices and supply chain disruptions. Additionally, technological advancements and increased R&D investments are driving innovation in the sector, improving product performance and efficiency.

Buy Now Premium Research Report: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=2754

Market Drivers

Rising Industrialization and Infrastructure Development: Rapid industrialization, particularly in emerging economies, is fueling demand for tool steels in construction, automotive, and manufacturing sectors.

Growth in Automotive and Aerospace Sectors: The need for precision components in the automotive and aerospace industries is driving the demand for high-quality tool steels.

Expansion of the Die and Mold Industry: With the increasing use of molds in plastic and metal forming applications, the requirement for durable and heat-resistant tool steels is on the rise.

Technological Advancements in Metallurgy: Innovations in heat treatment and alloying techniques are enhancing the performance characteristics of tool steels, making them more efficient and long-lasting.

Increase in Precision Machining Applications: The rise in complex machining processes in industries such as electronics and medical devices is pushing demand for high-grade tool steel.

Market Restraints

Despite its growth potential, the tool steel industry faces several challenges:

High Production Costs: The manufacturing of tool steel involves high energy consumption and expensive raw materials, making it cost-intensive.

Fluctuating Raw Material Prices: Price volatility of key alloying elements like tungsten, molybdenum, and vanadium affects market stability.

Environmental Regulations: Stringent regulations related to emissions and waste disposal from steel manufacturing pose challenges for market growth.

Competition from Substitute Materials: The development of alternative materials such as carbide and ceramic-based tools may limit the demand for traditional tool steels.

Supply Chain Disruptions: Global supply chain issues, including transportation delays and material shortages, impact production and pricing.

Tool Steel Market Segmentation

Tool Steel Format Type Outlook

Round Format

Square Format

Other Format

Tool Steel Application Outlook

Automotive

Machinery and Shipbuilding

Tool Steel Process Outlook

Forged

Browse In-depth Market Research Report: https://www.marketresearchfuture.com/reports/tool-steel-market-2754

Rolled Future Trends

The future of the tool steel market looks promising with ongoing advancements in materials science and manufacturing technologies. Some key trends expected to shape the industry include:

Increased Focus on Lightweight Materials: Manufacturers are exploring lightweight yet durable tool steels for improved efficiency and cost-effectiveness.

Automation and Smart Manufacturing: The integration of automation and AI-driven processes in tool steel production will enhance efficiency and reduce waste.

Sustainable and Green Manufacturing: Eco-friendly production methods and recycling initiatives will gain momentum in the industry.

Growth in Electric Vehicle Production: As EV adoption increases, specialized tool steels will be needed for lightweight and high-precision components.

Advancements in Coating Technologies: The development of advanced surface coatings will improve tool steel longevity and performance.

The tool steel market is poised for steady growth, driven by industrial expansion, technological advancements, and the need for high-performance materials. While challenges such as high production costs and environmental regulations exist, continuous innovation and strategic investments in metallurgy and manufacturing techniques are expected to overcome these hurdles.

With increasing demand from key industries such as automotive, aerospace, and construction, the future of the tool steel market remains promising. Stakeholders in the industry should focus on sustainability, efficiency, and innovation to maintain competitiveness and meet evolving market demands.

More Related Reports:

Floor Polishing Machine Market: https://www.marketresearchfuture.com/reports/floor-polishing-machine-market-8329

Soldering Equipment Market: https://www.marketresearchfuture.com/reports/soldering-equipment-market-8330

Drill Press Market: https://www.marketresearchfuture.com/reports/drill-press-market-8434

Industrial Vacuum Cleaner Market: https://www.marketresearchfuture.com/reports/industrial-vacuum-cleaner-market-8443

Industrial Noise Control Market: https://www.marketresearchfuture.com/reports/industrial-noise-control-market-8459

𝐀𝐛𝐨𝐮𝐭 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐅𝐮𝐭𝐮𝐫𝐞

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research Consulting Services. The MRFR team have a supreme objective to provide the optimum quality market research and intelligence services for our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Market Research Future

Market Research Future

+ +1 855-661-4441

email us here

Visit us on social media:

Facebook

X

LinkedIn

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release